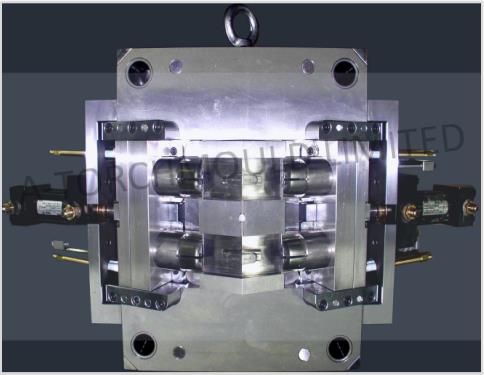

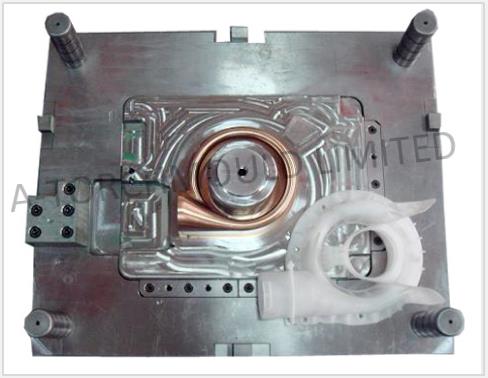

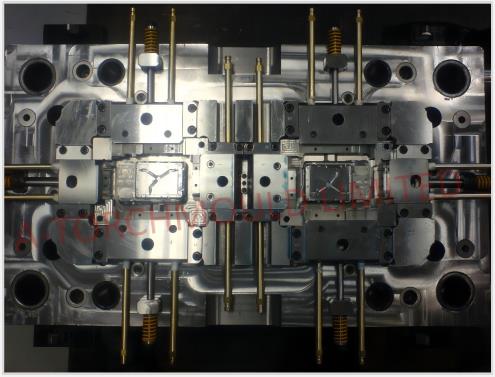

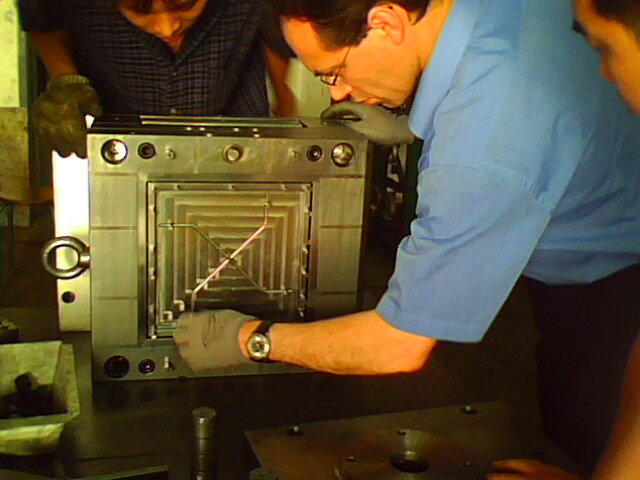

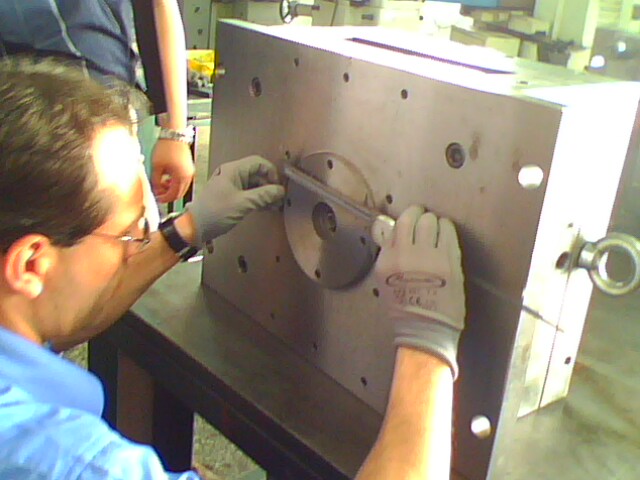

A-TorchMould Limited has commonly used in high-precision processing equipments, such as CNC machining center, Wire Cut Electrical Discharge Machining, Grinding Machine, Milling Machine, injection machine, etc. Complex shapes and contours are not a problem for our CNC professionals. Using all of the latest mold design concepts, our molds are built with precision and made to last. With in-house CNC, EDM, and polishing, we have full control of the mold making process.

Our engineering staff is rich in combined experience developing and designing all types of molds. With this experience working for you, you can be sure that your tooling project will be engineered with the highest level of reliability, and maintainability found in the industry.

CNC Machine

EDM Machine

Wire Cut

QC Equipment

According to the product function, structure, combined with customer requirements, we will reasonable choice mold steel and mold parts.

Mold base: DME, HASCO, FUTABA, LKM

Hot runner: DME, HUSKY, MOLD-MASTER, YUDO, HOTSYS, HASCO, SYNVENTIRE

Mold steel: P20/1.2311、H13/1.2344、718/1.2738、420/1.2316、S136/1.2083、420SS, etc.

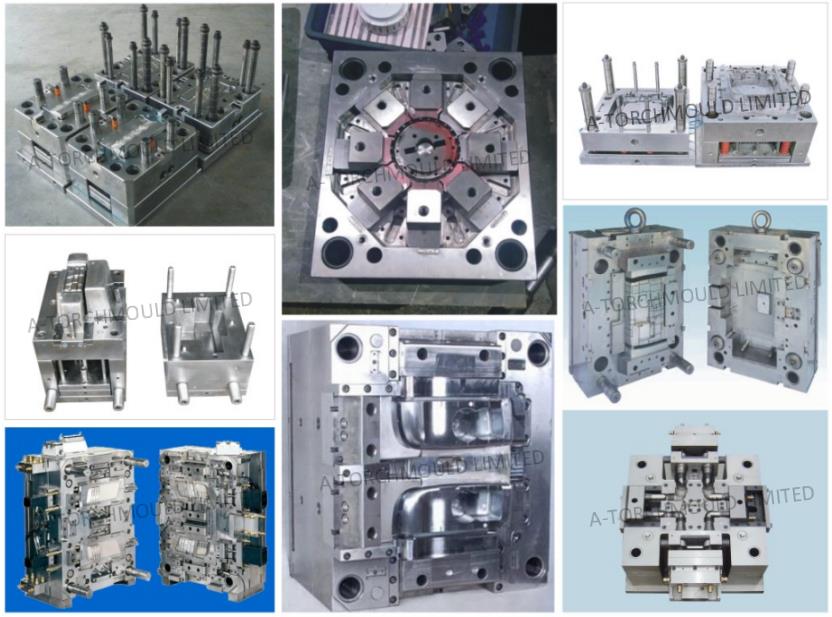

Our services include:

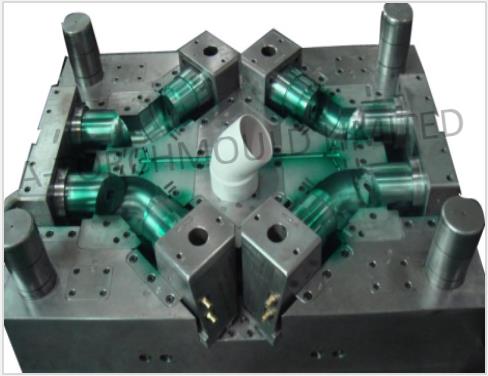

- Cold & Hot runner mold

- Single & Multi-cavity mold

- Insert Mold & Over Mold

- Prototype Tool

- Die Cast – Aluminum & zinc tool etc…

Inspection

Shipping